Description

氙灯耐候试验箱

产品介绍:

耐候试验是科硏生产过程中筛选配方优化产品组成的重要手段,也是产品质量检验的一项重要内容,长崎TK-XD系列氙灯耐候试验箱可模拟和强化在自然气候中受到的光、热、氧、湿度、降雨为主要老化破坏的环境因素,应用材料如涂料、塑料、铝塑板、以及汽车安全玻璃等产品标准均要求做耐候性试验。

The atmospheric exposure test is an important way to select the ingredients and optimize products in the research. It s also an important work in the products quality examination. The Nagasaki TK-XD xenon lamp aging test machine can simulate major factors in the environment which may lead to the damage like: light heat humidity rain. The product standard of the applied material like paint, plastic, aluminum panels, and automotive safety glass require the atmospheric exposure test.

造成材料老化的主要因素是阳光和潮湿。氙灯试验机可以模拟由阳光、雨水和露水造成的危害。本试验箱利用氙灯模拟阳光照射的效果,利用冷凝湿气模拟雨水和露水,被测材料放置在一定温度下的光照和潮气交替的循环程序中进行测试,用数天或数周的时间即可重现户外数月乃至数年岀现的危害。人工加速老化试验数据可以帮助选择新材料,改造现有材料,提升产品品质。

The major reasons of the material aging are sunlight and humidity. Xenon lamp atmospheric exposure test can simulate the damages cause by the sunlight, rain and dew. This machine uses the xenon and the condensed steam simulates the sun and the rain respectively. The material was tested under the cyclic program of sunlight and humidity Revitalizing the years or months of outdoors damage within a few days or weeks. The human accelerating aging experiment data can help people to choose new materials, to optimize the current materials and to improve the products quality.

执行与满足标准及试验方法:

1、GB/T4797-2006/IEC607212-4:2002 太阳辐射与温度试验方法

2、GB/T3511-2008/ISO4665:1998 硫化橡胶或热塑性橡胶耐候性

3、GB/T2423.24/1995/IEC68-2-51975 太阳辐射实验方法

4、GB-T12831-1991 (氙灯)老化实验方法

5、GB-T1865-2009/ISO11341:2004 氙弧辐照实验方法

6、GB-T2423.2-2008/IEC60068-2-2:2007 高温实验方法

7、GB-T24234-2008/IEC6008-2-30:2005 交变湿热方法

8、GB-T5170.18-2005 温度/湿度组合回圈设备

9、GB-T10586-2006 湿热实验箱技术条件

10、GJB150.7A-2009 湿热实验方法

11、GJB150.3A-2009 高温实验方法

产品实物参考图:

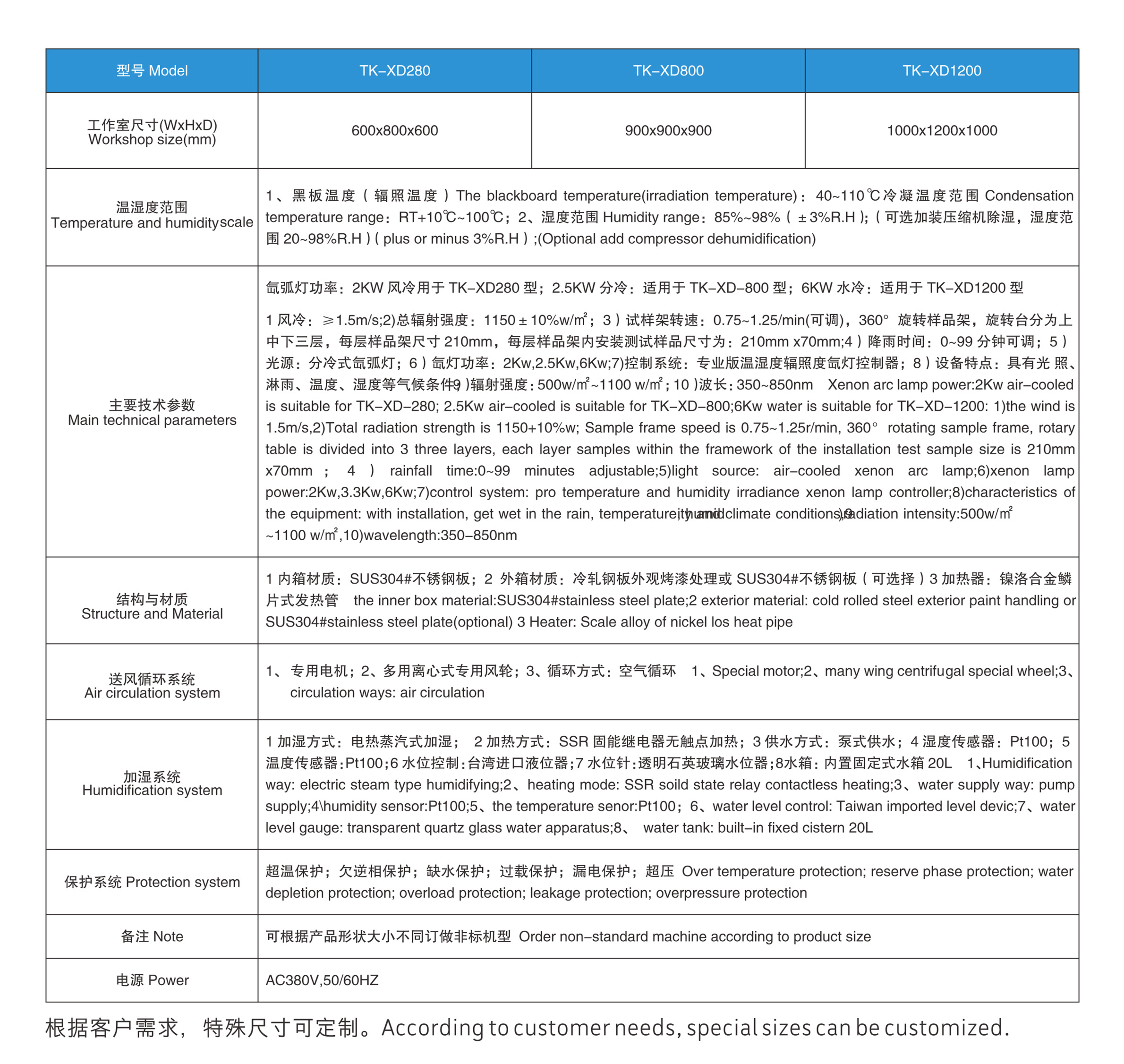

氙灯耐候试验箱

Reviews

There are no reviews yet.